- Hand Held or Bench Mounted

- Involute

- Serrations

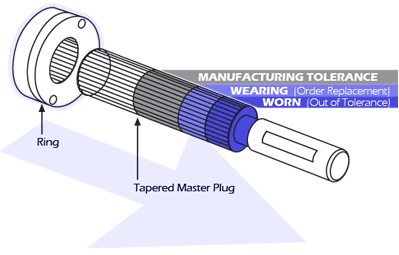

Taper Master Plugs (TMPs) are used for the manufacture and checking wear condition of ring gauges. A TMP has three lines inscribed as depicted in the diagram below; a new ring will be manufactured to fit between the first two lines. When the ring passes over the third line, the ring is worn.

When a TMP is used in the manufacturing of new rings, it ensures that all new ring gauges are consistent in size and allow you to monitor ring wear simply and accurately. This is useful when multiple rings are supplied to be used by subcontractors and end users.

Spline Ring & Plug Options:

Maximum effective tooth thickness –

Go Composite Ring Gauges provide a basic check of the maximum effective tooth thickness of an external spline component.

Minimum effective space width –

Go Composite Plug Gauges provide a basic check of the minimum effective space width of an internal spline component.

Minimum actual tooth thickness –

NoGo Sector Ring Gauges provide a basic check of the minimum actual tooth thickness of an external spline component.

Maximum actual space width –

NoGo Sector Plug Gauges provide a basic check of the maximum actual space width of an internal spline component.

Minimum effective tooth thickness –

NoGo Composite Ring Gauges provide a basic check of the minimum effective tooth thickness of an external spline component.

Maximum effective space width –

NoGo Composite Plug Gauges provide a basic check of the maximum effective space width of an internal spline component.

The best gauges start with the most appropriate material in each use case.

Let us know what you need or allow our engineers to recommend the best options.

WPS – Oil hardening tool steel hardened to Rc 60-62.

WPX – A powdered metal high speed steel hardened to Rc 62-64; noted for its higher wear resistance without sacrificing toughness. Recommended for high frequency gauges.

WPZ – A powdered metal high speed steel hardened to Rc 64-66; extremely high wear resistance and moderate toughness. Recommended for master gears.